>

>

An environment friendly water and sewage pipe with an economic efficiency, sanitation security and coating performance through coating BPF epoxy powder at inner side of ductile cast iron pipe

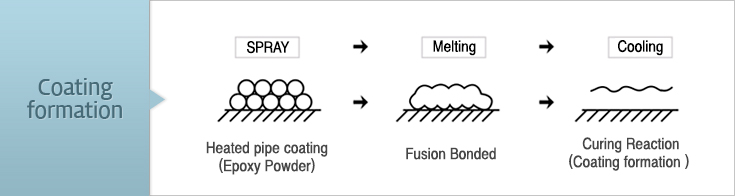

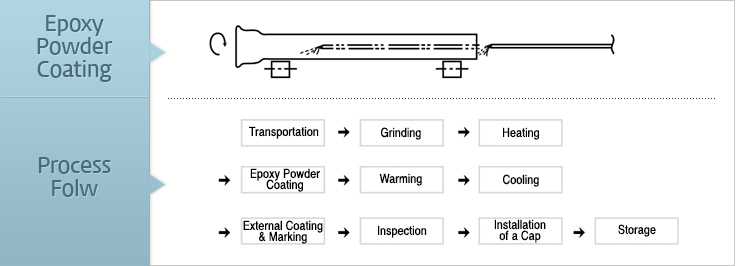

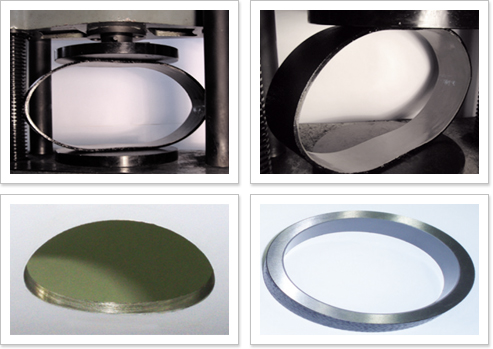

2. Coating Method

2. Coating Method

| Pipe Size (mm) |

Outside Diameter (mm) |

Weight of the Epoxy coated pipe (kg) |

Weight of the Cement mortalr lined pipe (kg) |

Reduced Weight (kg) |

|---|---|---|---|---|

| 80 | 98 | 85.9 | 95.2 | -9.7 |

| 100 | 118 | 104.1 | 115.6 | -9.9 |

| 125 | 144 | 133.4 | 148.2 | -10.0 |

| 150 | 170 | 160.7 | 178.2 | -9.8 |

| 200 | 222 | 215.3 | 238.2 | -9.6 |

| 250 | 247 | 281.8 | 310.2 | -9.1 |

| 300 | 326 | 358.4 | 418.0 | -14.3 |

| 350 | 378 | 442.9 | 512.8 | -13.6 |

| 400 | 429 | 532.5 | 612.0 | -13.0 |

| 450 | 480 | 628.0 | 718.4 | -12.6 |

| 500 | 532 | 737.6 | 837.0 | -11.9 |

| 600 | 635 | 973.7 | 1,092.4 | -10.9 |

| Property | Test Method | Requirement | Result (BPF Epoxy) |

|---|---|---|---|

| Adhesive Forces | Cross Cut 1x1mm | 100/100 | GOOD |

| Impact Resistance (1/2"bol*1kg) |

0.6t CRS | No Cracking | No Cracking |

| 6T Steel Plate | No Cracking | No Cracking | |

| Hardness | Mitsubishi Uni | H | H |

| Acid Resistance | 5% CH3COOH x 240hrs | Pass | |

| Corrosion Resistance | S.S.T. 500HRS | Coating disbondment Below 2mm |

Pass |

| Chemical Resistance | 90 DAYS at 20˚c | ASTM G 20 | Pass |