>

>  .

.

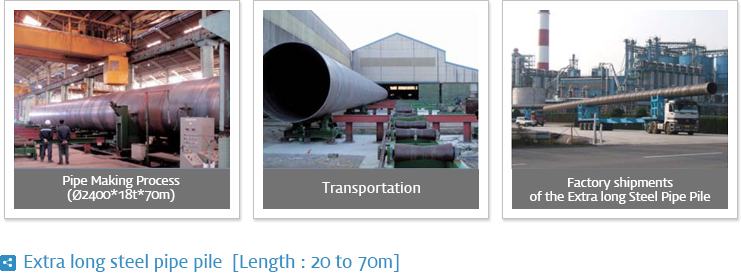

| 01No need for circumferential welding at site. |

spiral tube mill and directly supplied to construction site, joint work at site is not necessary. |

| 02No need to worry about welding quality. |

and no other inspection on orbital welding part is necessary. |

| 03Excellent straightness. |

straight and there is no shrinkage and distortion caused by cooling of welding part. Furthermore, since single pipe connection at site is not necessary, there should be no anxiety on straightness(bending) caused by connection of single pipe. |

| 04Can shorten construction period. |

welding part, inspection, and delivery time to construction time. On the other hand, extra long steel pipe pile can be constructed right away once it is delivered to construction site so to shorten the construction period. |

| 05Has an excellent economic efficiency and can reduce much cost. |

construction period. So, it increases the efficiency by shortening the time on site welding and decreases the cost on construction and non-destructive inspection. Thus, it can save lots of cost compared to that of site joint work and much more convenient and safer construction can be realized and the product quality has a higher reliability. |